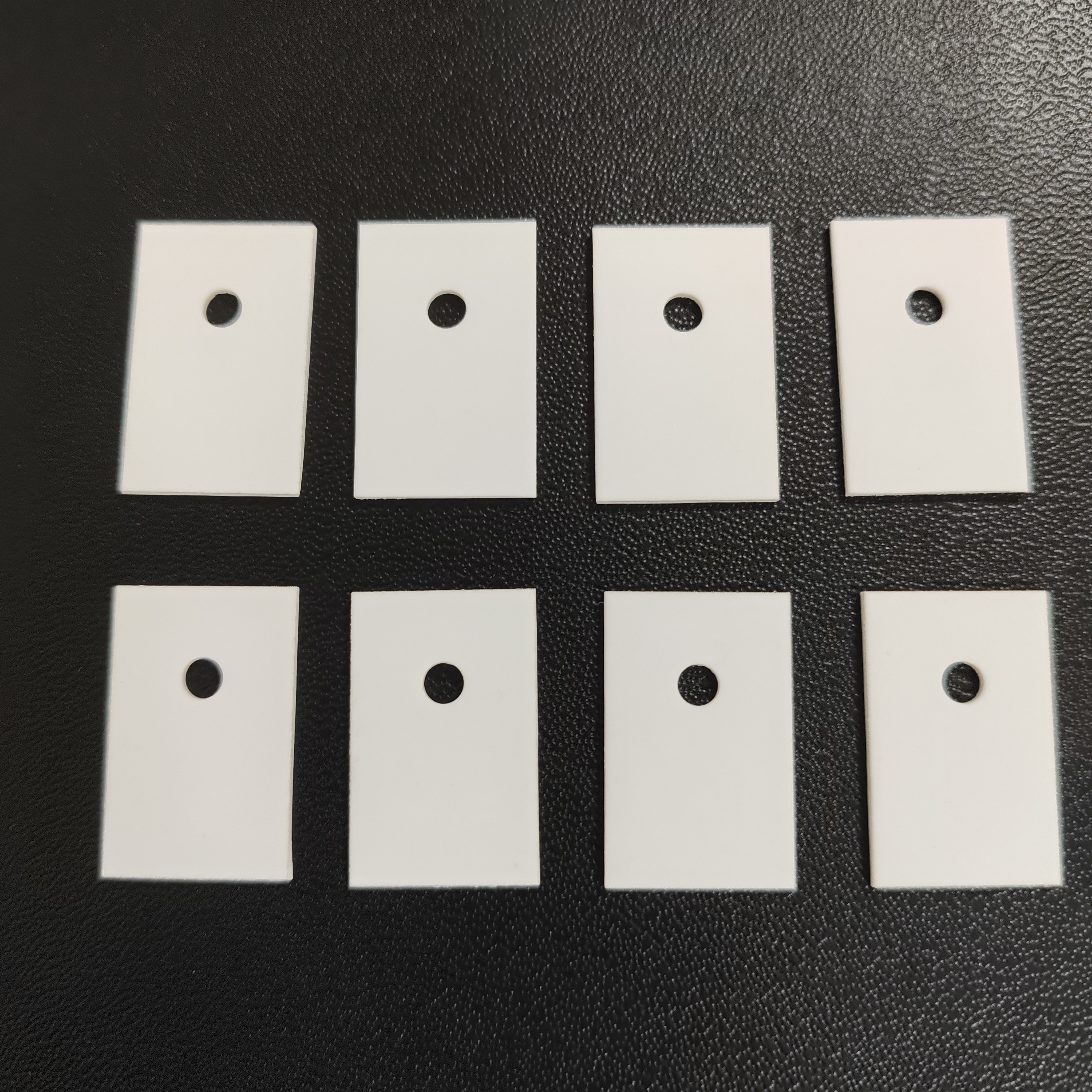

TCG- Thermal conductive gel series products are a two-component preformed thermal conductive silica gel products, which mainly meet the needs of low stress and high modulus of compression when the products are used, and can realize automatic production; It has good contact with electronic products during assembly, showing low contact thermal resistance and good electrical insulation characteristics. The cured thermal conductive adhesive is equivalent to thermal conductive gasket. It has good high temperature resistance and aging resistance, and can work at -40~180 ℃ for a long time.

TCG Thermal conductive gel series parameter properties | ||||||

Test item | Specification | Test Method | ||||

Product | TCG120 | TCG150 | TCG200 | TCG300 | TCG400 | / |

Composition | Silica gel + ceramic | / | ||||

Colour/Component A | White | White | White | White | White | Visual inspection |

Colour/Component B | Yellow | Green | Grey | Light Blue | Blue | Visual inspection |

viscosity/Component A (cps) | 120,000 | 250,000 | 300,000 | 250,000 | 4000,000 | ASTM D2196 |

viscosity/Component B (cps) | 120,000 | 280,000 | 320,000 | 260,000 | 4000,000 | ASTM D2196 |

Mixing ratio | 1:1 | / | ||||

Denstiy(g/cc) | 1.8 | 1.9 | 2.0 | 3.0 | 3.2 | ASTM D792 |

Hardness after curing(Shore 00) | 45 | 50 | 50 | 50 | 50 | ASTM D2240 |

Temperature resistance range(℃) | -40~180 | / | ||||

Electrical properties after curing | ||||||

Breakdown Voltage(Kv/mm) | ≥7.0 | ASTM D149 | ||||

Volume resistivity(Ω.cm) | 1013 | ASTM D257 | ||||

Dielectric constant(@10MHz) | 5.0 | 5.0 | 5.0 | 7.00 | 7.30 | ASTM D150 |

Fire rating | V-0 | UL 94 | ||||

Thermal conductivity after curing | / | |||||

thermal conductivity(W/m-k) | 1.2 | 1.5 | 2.0 | 3.0 | 4.0 | ASTM D5470 |

Product features

● Thermal conductivity: 1.2, 1.5, 2.0, 3.0, 4.0w/m.k

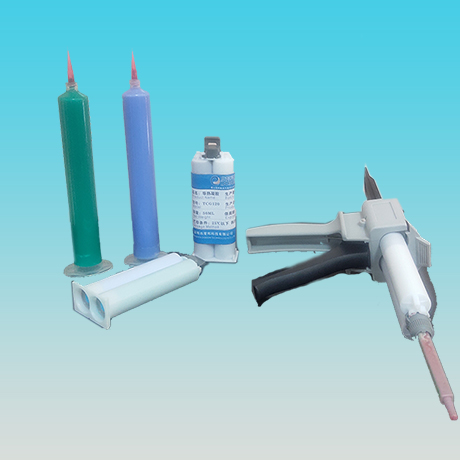

● Low viscosity and easy dispensing.

● Low pressure compression application.

● The curing time is adjustable.

●Excellent high and low temperature mechanical and chemical stability.

Typical applications

l Automotive electronics

l Optical fiber communication equipment

l SSD

l Netcom equipment and modules

l Between heating semiconductor and radiator

l Between battery pack and cold plate

Telephone

Telephone