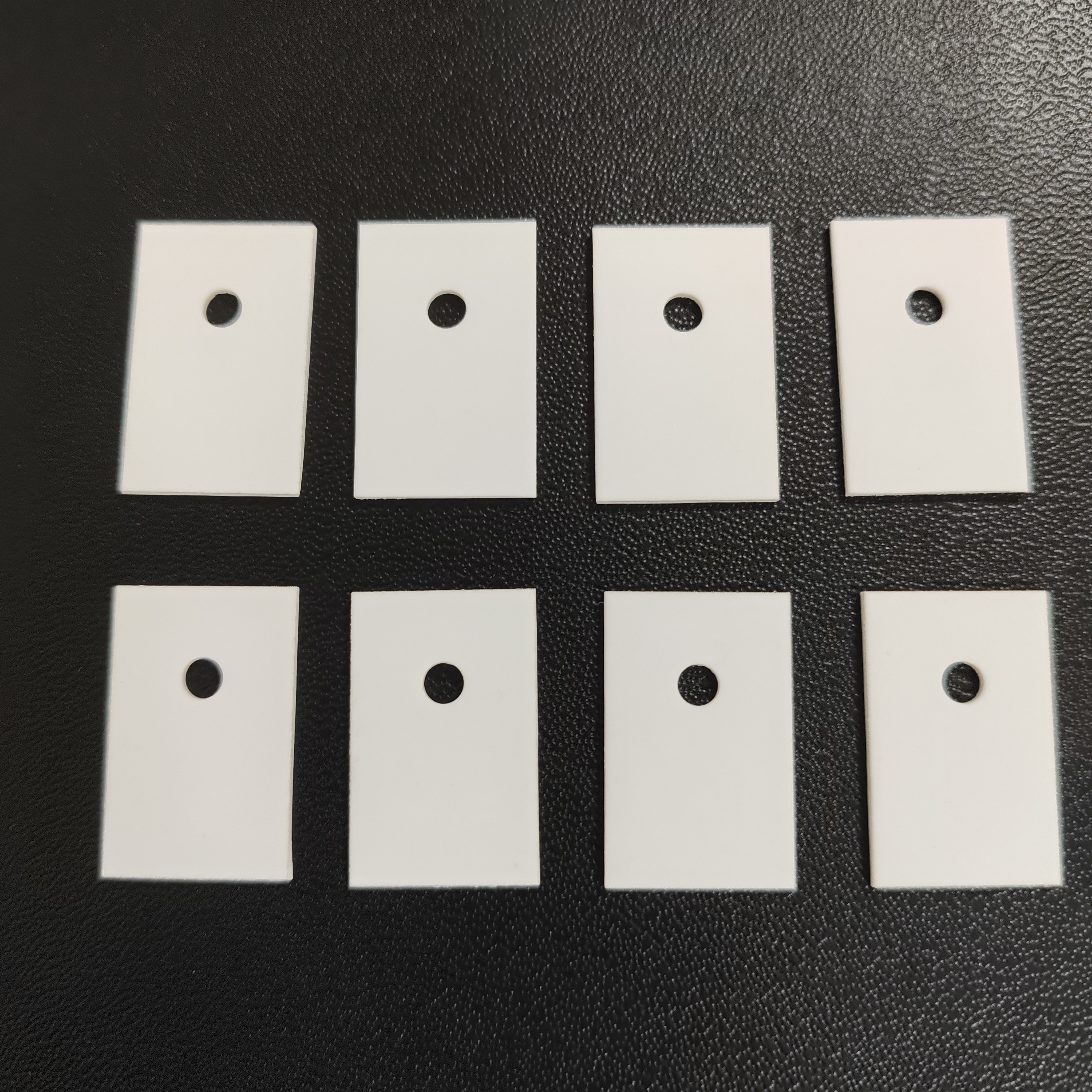

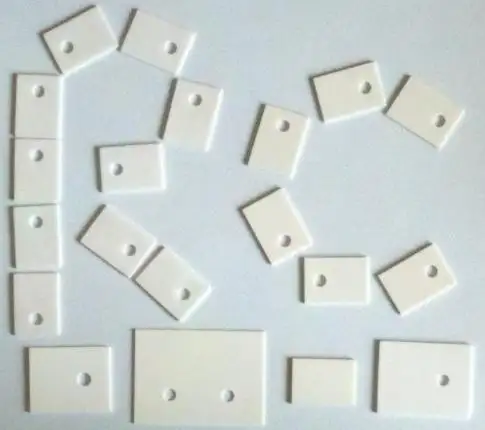

TC240 Aluminum oxide thermal conductive ceramic sheets are manufactured using high-purity selected raw materials and special processes. They have a high thermal conductivity of 24W/m.k. The surface is flat and smooth, and when used with silicone grease, it can effectively reduce contact thermal resistance. They have high strength and are not easy to break, high temperature and high pressure resistance, high insulation strength, acid and alkali corrosion resistance, and are durable.

Product features:

● High thermal conductivity, high insulation strength, and high temperature resistance

●High hardness and strength

●Wear resistance, acid and alkali corrosion resistance

●Simple structure and small volume

●The surface is flat and smooth, with even heating

Test items | Unit | Alumina96%Al2O3 |

Specific Gravity | g/cm3 | 3.9 |

Water absorption rate | % | 0 |

Thermal expansion coefficient | 10-6/K | 8.5 |

Young's modulus of elasticity | GPa | 340 |

Poisson's ratio | - | 0.22 |

Hardness(HV) | MPa | 1650 |

Bending strength (Room temperature) | MPa | 310 |

Compressive strength | MPa | 2200 |

Toughness | MPa'm1/2 | 4.2 |

Thermal conductivity (Room temperature) | W/m K | 24 |

Dielectric Strength | KV/mm | 10 |

Long-term operating temperature | ℃ | 1480 |

Specific resistivity | Ω.mm2/m | >1016 |

Maximum temperature (No load) | ℃ | 1750 |

Acid and alkali corrosion resistance | — | Strong |

Refractoriness | ℃ | 2000 |

Telephone

Telephone